How are shipping containers made?

Shipping containers, made from robust Corten steel, undergo meticulous manufacturing steps including cutting, welding, and protective measures to ensure strength and durability during transportation and storage.

Shipping containers are manufactured using durable steel materials. The process commences with a large sheet of steel that is subsequently cut into smaller sections. These sections are then corrugated and welded together to enhance their strength and structural integrity.

The majority of shipping containers are constructed from a type of steel known as Corten steel, also referred to as "weathering steel". Corten steel is an alloyed steel that contains other metals which react when exposed to air and water. This reaction leads to the formation of a protective layer of oxidation that prevents further corrosion of the metal.

Let's delve into the manufacturing process of shipping containers:

It all begins with a sizable sheet of steel, serving as the foundation for each container. This sheet is carefully cut into multiple pieces. To ensure cleanliness and eliminate any impurities, the sheets undergo sand-blasting and priming.

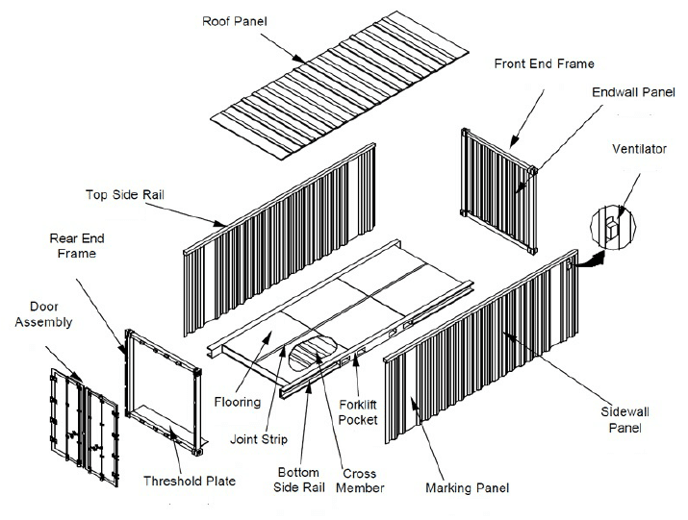

During the subsequent stages, the sheets are corrugated to enhance their strength, and the wall panels are expertly welded together. Additionally, square tubing is welded to the top of the walls for added reinforcement. The floors of the containers are meticulously crafted using sturdy and resilient wood that has been treated with a protective spray to prevent insect infestations. The floor panels and frame are produced separately. The door and corner post assembly follows suit. Firstly, the doors are installed on the floor frame, followed by the attachment of the wall panels. Subsequently, the corner posts, walls, and doors are skillfully welded in place, and finally, the roof panel is assembled and securely attached.

The concluding stages of the manufacturing process involve priming and painting the container to safeguard it against weather-related damage. Furthermore, the flooring panels are carefully varnished to shield the wood from potential water damage, and the floor is then installed within the frame. Rubber seals are fitted onto the doors to ensure a watertight seal, and the bottom of the container is made water-resistant.

By following these meticulous manufacturing steps, shipping containers are created to withstand the rigors of transportation and provide reliable storage solutions.